More than 8 different types of coolant liquids are already stipulated as a mandatory requirement by car manufacturers. Severe engine damage is often the result of a malfunctioning cooling system due to the use of the wrong coolant. Modern cars, with a combustion engine, are equipped with high-tech, complex cooling systems.

These systems consist of different metals (for example, cast iron, stainless steel, aluminum, magnesium, brass) which each have different properties. For the engine to function smoothly, it is essential to only use the right coolant. Car manufacturers each have their own requirements regarding the correct coolant. It is therefore crucial to strictly follow these requirements.

The function, operation, and composition of coolants

A combustion engine generates a lot of heat during the combustion of fuel (gasoline, diesel or LPG). This heat must be dissipated to prevent the engine from overheating, which irrevocably leads to severe engine damage. The coolant plays an essential role in the dissipation of this heat. A good coolant must meet the following requirements:

- Must have excellent heat transfer properties.

- Should not solidify or freeze at low temperatures.

- Must have a high boiling point to prevent vapor bubbles from forming.

- Must protect the internal part of the engine and cooling system against corrosion, erosion, and cavitation.

- Must not affect the materials used.

- Must not foam.

Most automotive coolants consist of a mixture of monoethylene glycol + demineralized water with the addition of various high-quality chemicals, also known as the additives package. In this MPM ‘OEM NewsLetter’ we (only) discuss this type of coolant, i.e. coolant which uses monoethylene glycol as the basis for its mixture. The boiling and freezing point in the coolant are determined by the percentage of monoethylene glycol or, put simply, “the more water it contains, the lower the freezing point”, and also the cheaper the product.

Antifreeze or coolant?

The terms antifreeze and coolant are often used interchangeably. MPM products with the name ‘Antifreeze’ are antifreeze products that still need to be diluted with demineralized water before use. These products are also referred to as ‘concentrate’. MPM products with the name ‘Coolant’ are ready-to-use and should never be diluted.

Protection of engine and cooling system by the type of coolant against corrosion

Coolant comes in direct contact with the various types of metals of which the engine and cooling system are made up, such as cast iron, steel, aluminum, magnesium, copper, brass, and solder. Protecting these metals against (electrochemical) corrosion, which would otherwise be a side-effect of the coolant, is essential. It is the coolant’s additives package that protects these special metals against corrosion. So the composition of the chemicals used in the additives package is an essential part of the coolant. The car manufacturer’s specifications for the coolant meet these requirements. So the primary function of these specifications is to optimally protect the metals used in the engine and the cooling system. The days are long gone when car manufacturers built engines exclusively from cast iron; nowadays special alloys such as aluminum and magnesium are the norm.

Organic and inorganic anti-corrosion additive technology

The protective additives in coolants, and along with that, also the two main types of coolant, can be divided into two main groups.

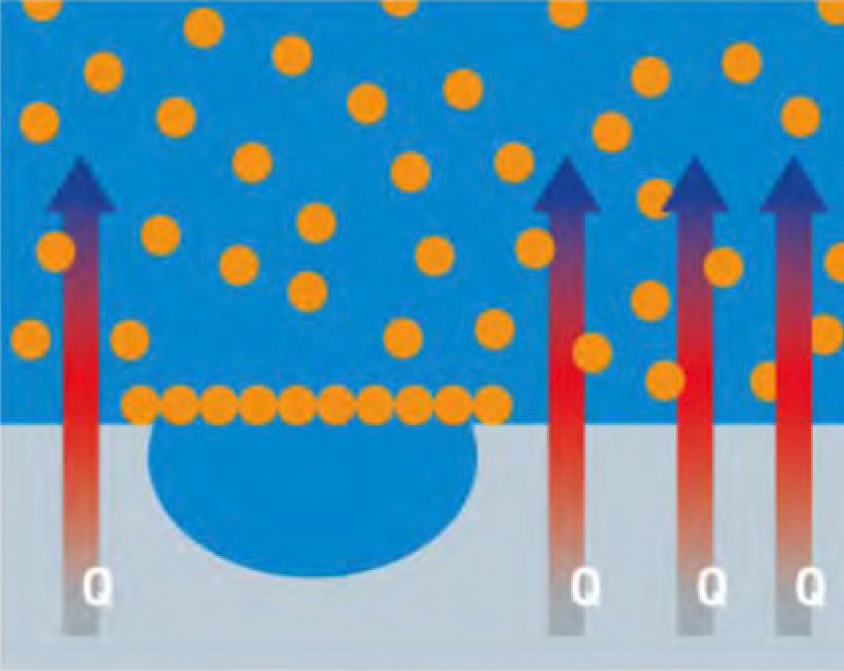

1. Inorganic additives technology (IAT):

The protective effect of this technology is based on the principle that the additives keep the metals that are used in the engine and cooling system, separate from the cooling fluid because the additives; for example silicate or phosphate, form a protective layer on the surface of the metals. This is traditional technology. This technology has two drawbacks. The additives package is exhausted relatively quickly, and the coolant must, therefore, be replaced at least every two years. In addition, the protective layer impedes the heat transfer, which is also a distinct disadvantage. The desire for longer change intervals, increasing demands from the coolant and the increasing use of alloys in engines, this technology has been replaced by the OAT technology (or combinations of the two technologies).

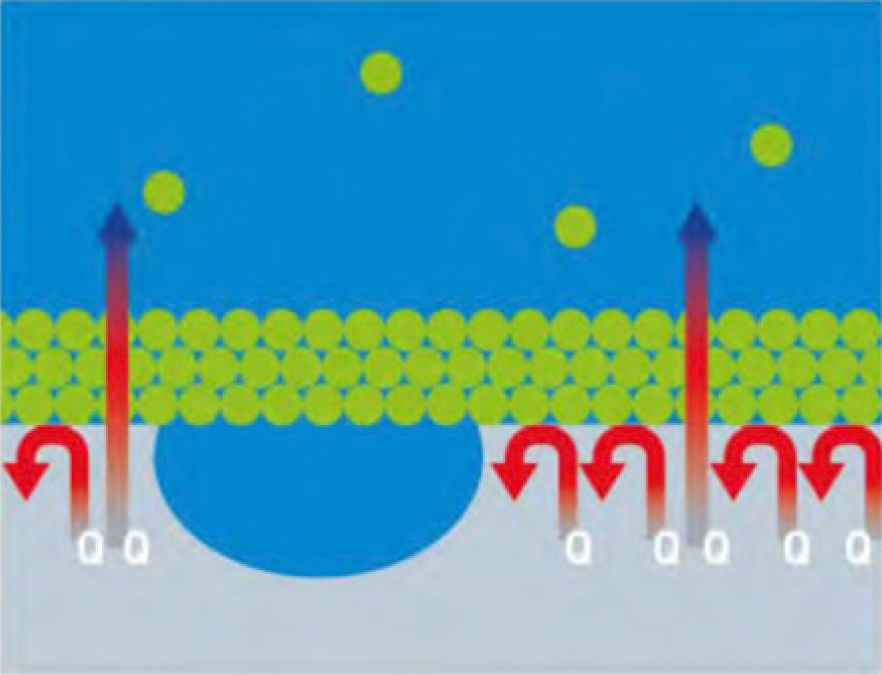

2. Organic additives technology (OAT):

The protective effect of this technology does not take place uniformly, but is only activated when corrosion is about to occur through a local chemical reaction with the metal. This offers many advantages, including better heat transfer and a long service life. Organic Additives Technology is a general term. The exact composition of the additives package explicitly differs per OEM specification.

Mineral inhibitor technology

Organic inhibitor technology

Hybrid technology

In addition to the two main groups, there are also combinations of these technologies, which combine the benefits of both technologies. These are the so-called hybrid products, whereby we distinguish between the so-called ‘hybrid products’ (>10% IAT) and ‘lobrid products’ (<10% IAT).

No universal coolant!

The metals used in the engine and cooling system of modern cars are sophisticated and vary tremendously. This is why the car manufacturer specifies the exact type of coolant in its OEM specifications. The composition of the additives in the coolants varies enormously. No coolant can meet all requirements; therefore universal coolant does not exist (anymore). There are so-called ‘universal’ or ‘multi-vehicle’ products on the market, which would, for example, be suitable for vehicles that require a G11, G12, G12+, G12++ or G13 coolant. These combinations are technologically impossible and can only be characterized as a ‘pipe dream’.

MPM recommends: only use the coolant specified by the car manufacturer. MPM can supply you with all OEM original, prescribed types of coolant through your trusted wholesaler.

For technical questions:

Please contact MPM Technical Support.

In summary:

- There is no such a thing as universal coolant (anymore).

- At this point, 8 different types of coolants are a mandatory requirement.

- The cooling system is an essential part of car technology. The use of the wrong coolant can result in severe engine damage.

- Cooling systems are becoming more and more complex, and the demands of coolant liquid are increasing accordingly.

- The protective effect of coolants are based on various technologies.

Tips for the workshop:

- Only use the coolants specified by the manufacturer. Check the MPM website to find out which coolant fluid is prescribed for which vehicle.

- There is no universal coolant: be wary of so-called universal / multi-vehicle coolants.

- Never mix different types of coolant (there are some exceptions. Always ask MPM for advice in such cases).

- Always replace the coolant after a leak in the head gasket has been repaired.

- The color of the coolant is only an indication of the type of product: it says nothing about quality. For example, some G12+ products are yellow or amber colored. These can best be topped up with the clear G12+ coolant (86000CBL) to prevent color deviations.

- Asian car brands often prescribe coolants containing hybrid phosphates (86000CLP). Products containing silicate should never be used in that case.

- G13 coolant contains glycerol. This means you need a special refractometer to read out the frost protection correctly.